Heavy clay ceramics

The heavy clay ceramics area includes information about brick production as well as ideas on optimization and resource-efficient manufacturing.

In terms of optimizing process technologies in production plants that manufacture heavy clay products, European ceramics manufacturers are following a road map up to the year 2050, which was unveiled in 2012. In line with this road map, forward-looking, brick solutions for the construction industry must be aligned with resource-efficient production processes for all types of bricks. This means that new concepts in dryer and industrial kiln construction, for example, can be used to boost energy efficiency. Tailored processing and shaping technologies enable bricks with improved insulation properties to be designed. These can then be used not only in new builds but also in another key area: the reconstruction of existing buildings undergoing energy retrofits.

You can also find out about the field of Raw materials, which is one of the most dynamic areas in the ceramics industry.

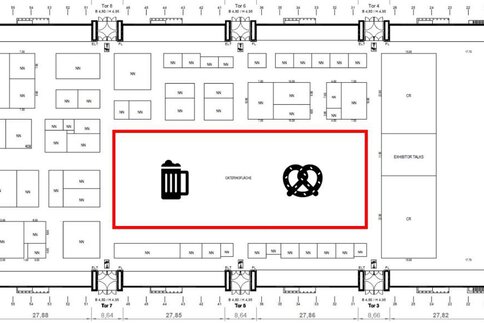

Hall A4 with a new look and feel

The redesigned Hall A4 will be the central meeting point of ceramitec. A newly designed catering area acts as a focal point for all visitors to the exhibition grounds and creates a lively atmosphere.

Exhibitors from the heavy clay ceramics sector have the opportunity to choose their preferred placement according to the "first come, first served" principle and thus benefit from the optimized design. The concept is complemented by a forum for exhibitor presentations and specialist lectures. This inspiring platform promotes the exchange of knowledge and the development of innovative solutions for current challenges in the heavy clay industry.

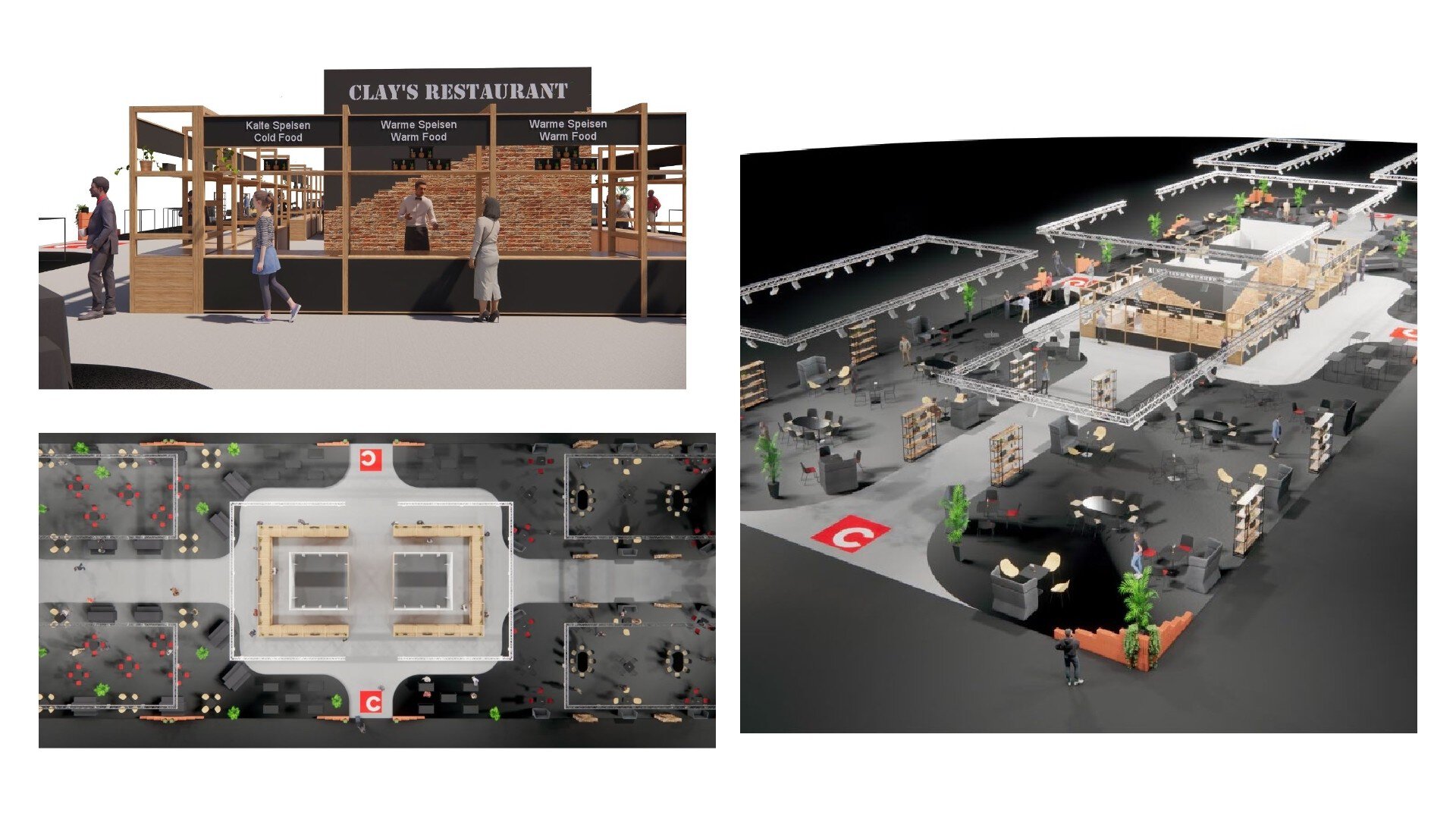

Clay's Restaurant at ceramitec 2026

Your direct way to ceramitec 2026!

All it takes is a few clicks to go online and purchase your personal ticket to ceramitec or directly redeem your voucher.