Raw materials and additives, powder, production materials, and ancillaries

The crucial role of raw materials and additives, as well as powders, production materials, and ancillaries in ceramic production processes, is highlighted through a dedicated exhibition area at ceramitec.

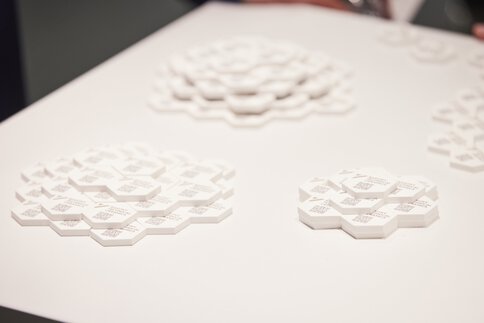

In the ceramics industry and in powder metallurgy, the quality of natural and synthetic raw materials and powders plays a key role in determining the efficiency of production processes and the properties of finished components. Organic and inorganic additives and ancillaries optimize the mixtures required for production here, making them perfect for processing. They also have a targeted effect on the material properties of end products. With increased requirements for material efficiency, raw material and powder suppliers are becoming more deeply involved in production technology.

This drive to raise efficiency is not just limited to optimizing input factors, i.e. the material used and the end product. There are also increasing requirements as regards recycling materials resulting from the production process, right up to the recycling of ceramic components that have already been utilized and have now reached the end of their life span.

In addition to ceramic raw materials, refractory materials and kiln furniture are a further important area related to processes and the properties of ceramics.

Marketplace for recycled materials

Are you looking for new customers for your recycled raw materials? Are you looking for partners from whom you can source recycled raw materials? Then become part of ceramitec's marketplace for recycled materials.

Learn more in our factsheet

Your direct way to ceramitec 2026!

All it takes is a few clicks to go online and purchase your personal ticket to ceramitec or directly redeem your voucher.